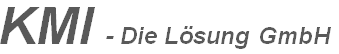

Training for Your Employees

– Knowledge for the Future

Expand knowledge, apply what has been learned, and build future-ready skills with KMI training programs. We provide hands-on expertise across all industries and applications within our portfolio, strengthening the long-term competitiveness of your company. Our application-specific courses are tailored to the needs of your employees and the requirements of your production. Innovative learning methods, personal support, and practice-oriented content ensure training that is effective, flexible, and sustainable – fostering professional excellence and personal growth.

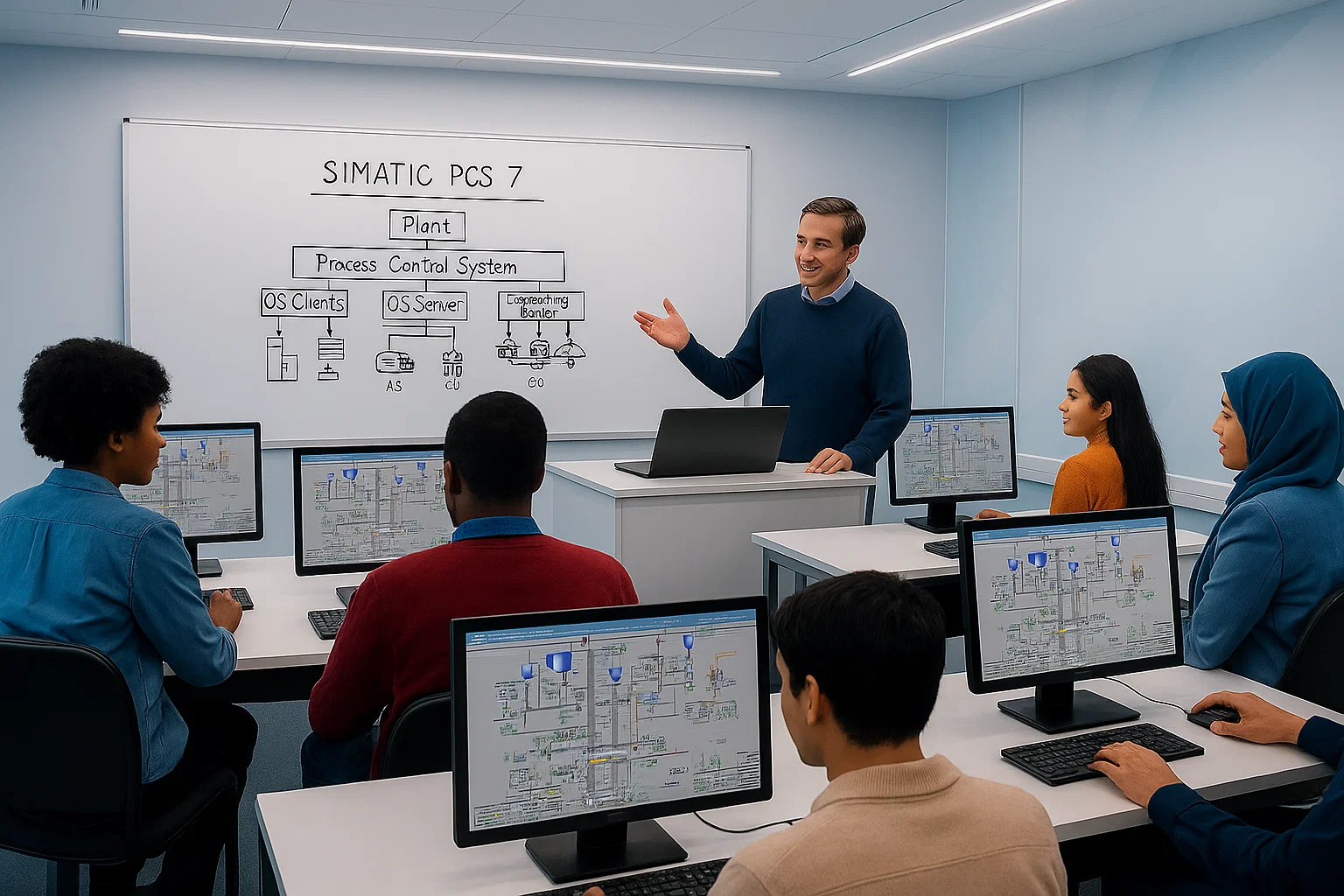

PCS7 Training

In this training, you will learn how to use the SIMATIC PCS 7 process control system efficiently – from the field level through control to the operator and monitoring system. In a virtual training environment, you will design the automation of a plant and deepen key topics such as system integration, data management, and project administration.

After completing the course, you will be able to:

- Correctly create PCS 7 multiprojects and configure hardware (AS/OS)

- Confidently use engineering tools such as CFC, SFC, and graphic editors

- Apply bulk data engineering with TML & Plant Generator

Project-Specific Training

We provide hands-on training on our software products and automation components – either alongside your project or prior to commissioning. Content and duration are flexibly tailored to your needs, ensuring that your plant can be operated safely and efficiently from day one. Whether it’s standards in hardware and software engineering, PLC control, or virtualization, we deliver the know-how and share our experience. Training can take place at our site, online, or directly at your plant – giving your team practical skills and confidence where they need them most.

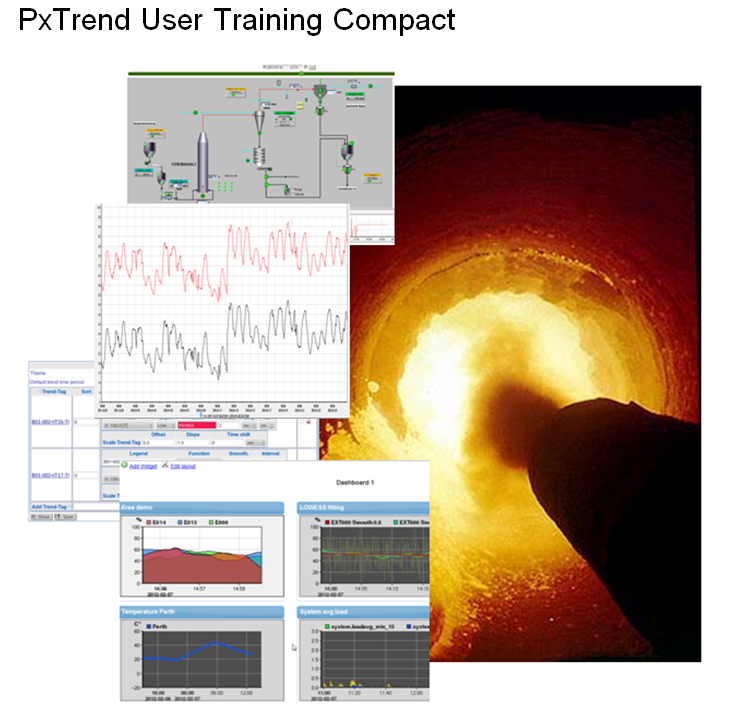

PX-Trend Training – Ready for Daily Production

This training enables users to operate and configure the PX-Trend archive and information system safely and effectively in daily production. The goal is to make production data and information consistently available across the entire company.

The training focus on:

- Use & configuration of metric data points

- Creation of graphic boards

- Setup of “playback” pages

- Configuration of message & information pages

- Working with dashboards

- Generating Excel reports

- Manual entries & programming of monitor objects

By the end of the course, participants will be able to adapt PX-Trend independently to their production needs – ensuring transparency, efficiency, and confidence in everyday plant operation.

Automate today, innovate tomorrow, excel forever.