Lab Automation with PxLab

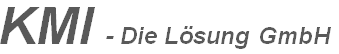

We integrate laboratory components from different manufacturers into one unified system. You choose the devices – such as samplers, pneumatic tube systems, mills, presses, and analyzers – and we combine them into a consistent, group-wide operable solution. Existing lab equipment can also be seamlessly integrated across plants or corporate networks.

The result: a modular, vendor-independent system tailored for the cement industry that reduces complexity, ensures consistent data, and increases efficiency in every step of your lab operations.

Core Functions

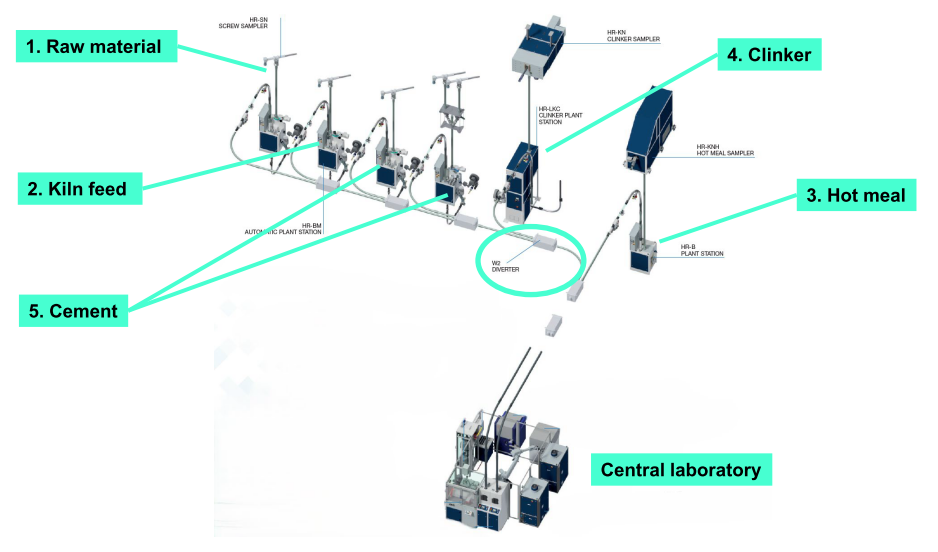

- Group-wide user interface via intranet / internet with web browser

- Freely configurable, login-dependent, multilingual user guidance

- Sample tracking and long time archiving

- Control of sample preparation and analysis equipment

- Integration of Sympatec, Malvern, ARL, Bruker and Panalytical Analyzer

- Integration of preparation systems from Herzog, Polysius, ITECA and FLS

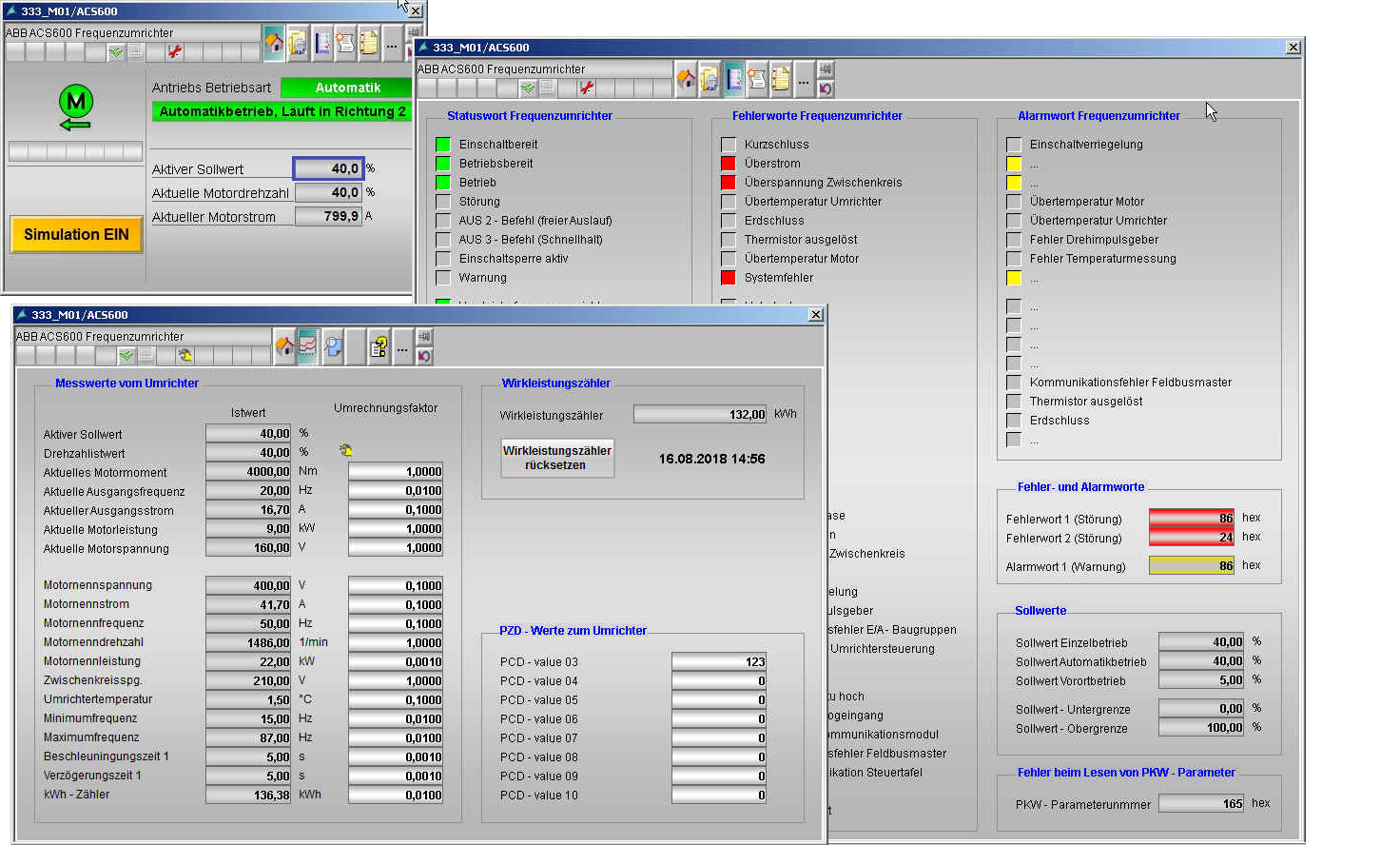

- Integration of the laboratory to local control systems (Siemens, ABB, etc.)

- Mix control based on captured analysis values

These functions create a standardized, transparent, and efficient lab environment – giving you consistent data, simplified workflows, and smarter decision-making across the entire production chain.

The Central Web Server

At the heart of the system is a web server that centrally collects all lab data and makes it available via browser – with no additional software required. Access is role-based and secured, available from any PC in the lab, the plant, or company-wide through intranet/internet. Users are provided with rights-based menus, independent of their workstation. All data is stored in an SQL database, ready for internal reports, external applications, and direct process parameterization. Maintenance and configuration can be performed flexibly from any workstation.

- For IT: reduced maintenance effort, simplified infrastructure, and higher security.

- For users: easy access, transparent data, and greater efficiency in daily operation.

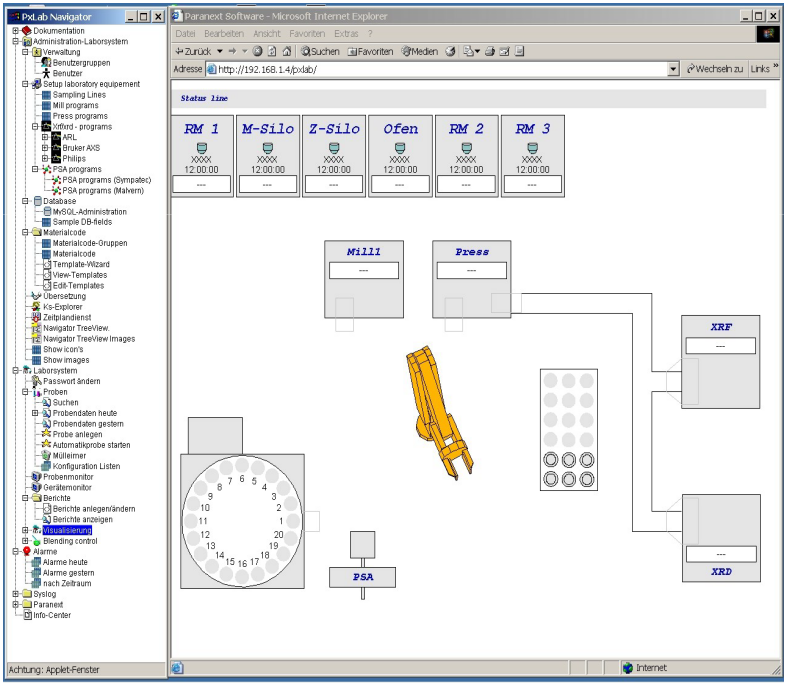

Mixing Control

PX-LAB enhances laboratory automation with a powerful mixing control system featuring an unlimited number of controllers and freely definable control targets. Any oxide combinations and constraints can be processed.

Extended PI controller settings are accessible directly via the web interface, allowing parameter adjustments either independently or with remote support. Comprehensive diagnostic and analysis tools enable complex control loops to be optimized scientifically – not just based on experience.

Supported Laboratory Equipment

The laboratory system natively supports the following equipment:

- Sample preparation: FLS, Herzog, Polysius

- Particle Size Analyzers: Sympatec, Malvern

- Analyzers: ARL, Bruker, Philips/Panalytical

- Color measurement: Dr. Lange, Minolta

- Cross-belt analyzers: ASYS / Gamma Metrics, Thermo

For IT: seamless integration reduces setup complexity and ensures long-term compatibility.

For users: broad equipment support provides flexibility, efficiency, and consistent data across the entire laboratory workflow.

Integration into your environment

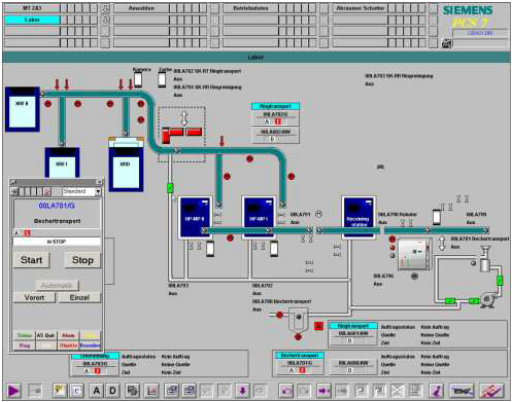

Our lab automation control system supports the SIMATIC S5 and SIMATIC S7 PLC families. It can run as a stand-alone solution or be integrated into CEMAT (from V2 to Version 10 / PCS 7) – ensuring seamless connection to your central control system at any time. Interfaces to samplers and receiving stations are managed via fieldbus, with both existing and new samplers integrated as intelligent slaves or decentralized peripherals. Already supported are screw samplers, pneumatic samplers, hot meal samplers, as well as manual stations (FLS, Herzog, Polysius). Thanks to its open PLC structure, virtually any sampler type can be connected. Material handling can be implemented either with conveyor belts or robotic technology.

The smooth connectivity with existing and new devices ensures reliable workflows and efficient sample handling.

Integration into CEMAT / Minerals

Our lab automation system is fully aligned with the interfaces of Siemens’ globally established CEMAT control system – from Version 1.8 (S5) up to the latest PCS 7 / Minerals. All laboratory PLC functions can be seamlessly linked with the command and messaging interfaces of CEMAT function blocks.

Motors and valves are controlled via CEMAT modules, ensuring that laboratory systems are fully integrated into the central control room. All interfaces are also compatible, providing uniform display, archiving, and maintenance of data and alarms.

Automate today, innovate tomorrow, excel forever.