Crane Automation

Integrating bulk material crane systems into a customer’s control system is often complex and rarely foreseen in existing setups. KMI provides a flexible solution: your process control system handles material management in the crane yard and sends individual tasks to the crane control – enabling efficient automation even for older installations. Operators can configure and control crane operations directly via the familiar user interface, visualize material flows and silo levels, and intervene manually whenever required. This approach not only streamlines integration and extends the lifetime of existing assets, but also ensures safe, efficient, and transparent crane operations.

Modernization of an Existing Plant

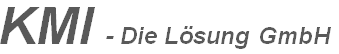

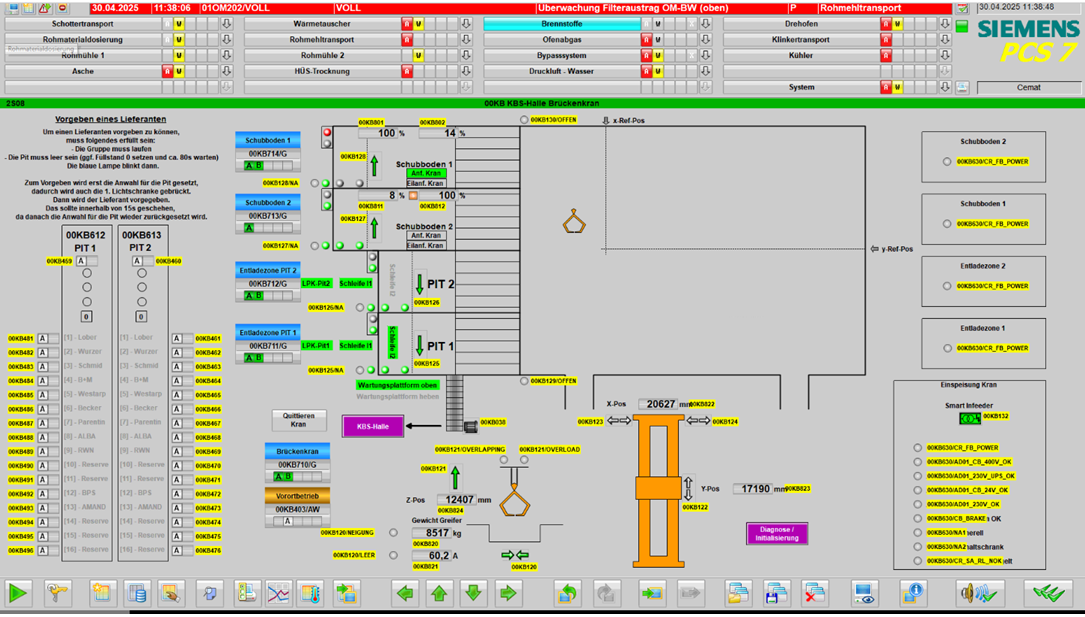

In a port crane system for ship unloading and supplying grinding plants, the mechanics remain intact while the outdated SIMATIC S7-300 control and legacy crane PC are modernized. We adapt the logistics to current requirements and integrate the system into the central PCS 7 / CEMAT control environment. The crane operates in both manual and automatic modes: ships are unloaded manually, while silos are filled automatically. New features such as recipe control, stockpile mixing, and flexible transport algorithms can be configured directly via WinCC – delivering higher efficiency, easier operation, and long-term future readiness.

Material Management

In cement plants, material supply must be guaranteed around the clock – even when raw materials and fuels are not delivered continuously. Efficient storage management is therefore essential to ensure uninterrupted production. Our crane automation combined with automated storage management maintains a constant material flow throughout the day and across the entire week. The result is reliable, safe, and efficient material management that secures consistent production and strengthens the overall performance of your plant.

Automate today, innovate tomorrow, excel forever.