Commissioning

Our team ensures a smooth and efficient commissioning of your production plants. With many years of experience in clinker and cement production, we guarantee precise and on-time execution. We develop tailored solutions to match your requirements and support you throughout the entire process. In addition, our experts train your staff to operate the system safely from day one. Rely on modern technologies and innovative approaches to take your automation to the next level.

Worldwide Commissioning

Our team carries out the commissioning of production control systems according to the latest machinery standards – worldwide, either on-site or remotely. This includes installation and start-up of process control systems, I/O checks, interlock and automation tests, integration of upstream and downstream processes, as well as process and controller optimization. We also handle parameterization of drives and other components. To ensure a smooth start, we provide training and instruction for your staff – so your plants run safely and efficiently from day one.

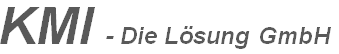

Optimization in Clinker and Cement Production

Efficient process optimization starts with approaches close to operations. Our strength lies in translating digital solutions into practical results for the cement industry. By combining proven control and optimization strategies with state-of-the-art data collection and analysis, we drive sustainable process improvements. With expertise spanning process engineering, machinery, and automation, we take a holistic view of cement production – delivering measurable efficiency gains and lasting performance benefits.

Commissioning Management

KMI takes responsibility for leading, coordinating, and supervising all commissioning activities in electrical and automation – from planning to handover. This includes preparing commissioning schedules, defining work packages, and organizing international specialists. We monitor tests of your suppliers and experts, ensuring compliance with all contractual and safety requirements on site. With targeted reporting, performance tests, approvals, and customer training, we secure a seamless transition to reliable plant operation – giving you confidence and control from day one.

Automate today, innovate tomorrow, excel forever.