Process Control Systems and Automation

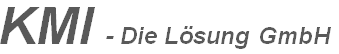

New production methods demand powerful automation – and strong software at the heart of operations. KMI provides comprehensive engineering services for process control systems and programmable controllers of the Siemens SIMATIC PCS7. Our expertise covers the full spectrum: from legacy systems such as SIMATIC S3, 110, 130, and 150A/K to the latest generations including SIMATIC S7, PCS 7, and TIA.

Process Control Systems and Controllers

Flexible manufacturing places ever higher demands on machines and production systems. Shorter innovation cycles enable operators to adapt quickly to market needs. At the same time, many plants now run a wide mix of automation systems from different generations. With decades of experience across multiple SIMATIC platforms,

KMI is uniquely positioned to engineer, integrate, and maintain this broad spectrum of devices with reliability and expertise.

Systems We Maintain and Support

| Process Control Systems | SIMATIC PC S7 / V 5.x – V10 CEMAT V1 – CEMAT V10 / Minerals CEMAT V4 / CEMCASE | |

| SIMATIC S7 | PLC Controller | S7 – 400 / S7 – 300 / S7-1500 |

| Communication Modules | Point to Point CP 411 Ethernet CP 443-1 Profibus CP 443-5 (DP/FMS) | |

| HMI Systems | WINCC / WINCC Flexible / TIA Coros LSB / LSC INTOUCH / Wonderware | |

| SIMATIC S5 | PLC Controller | S5 – 115U, S5 – 135U, S5 – 155U S5 – 130W/K, S5 – 150K/S S5 – 95U, S5 – 100U |

| Weighing System | Siwarex S, Siwarex M |

PCS 7 with CEMAT / Minerals

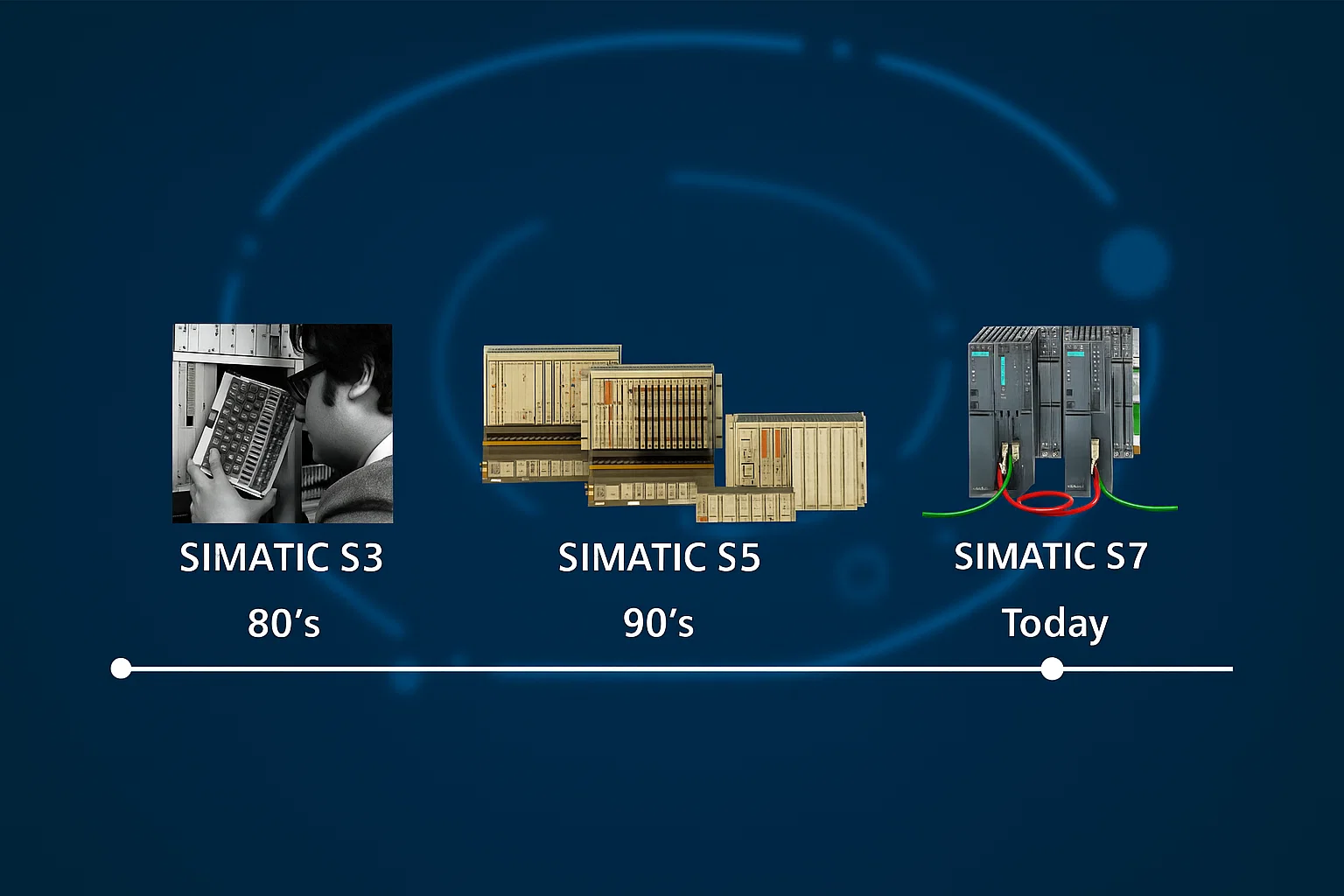

With the integrated, modular PCS 7 control system, we respond quickly and flexibly to customer requirements. Its scalable architecture and powerful engineering tools enable seamless automation of the entire production process. We emphasize clear, user-focused visualization and messaging.

Our applications cover everything from basic control tasks to advanced optimization, including energy management and peak load systems – giving you full transparency, reliability, and control over your production.

CEMAT / Minerals

For more than 50 years, CEMAT has been Siemens’ proven, flexible, and innovative process control system for the global cement industry. Its open architecture and seamless integration into PCS 7 provide a future-proof and cost-efficient solution for plants of any size.

Transparency is key to reliable processes and higher productivity – and this is where CEMAT excels: combining advanced process automation with digitalization and highly reliable instrumentation across all phases of cement production.

CEMAT and KMI

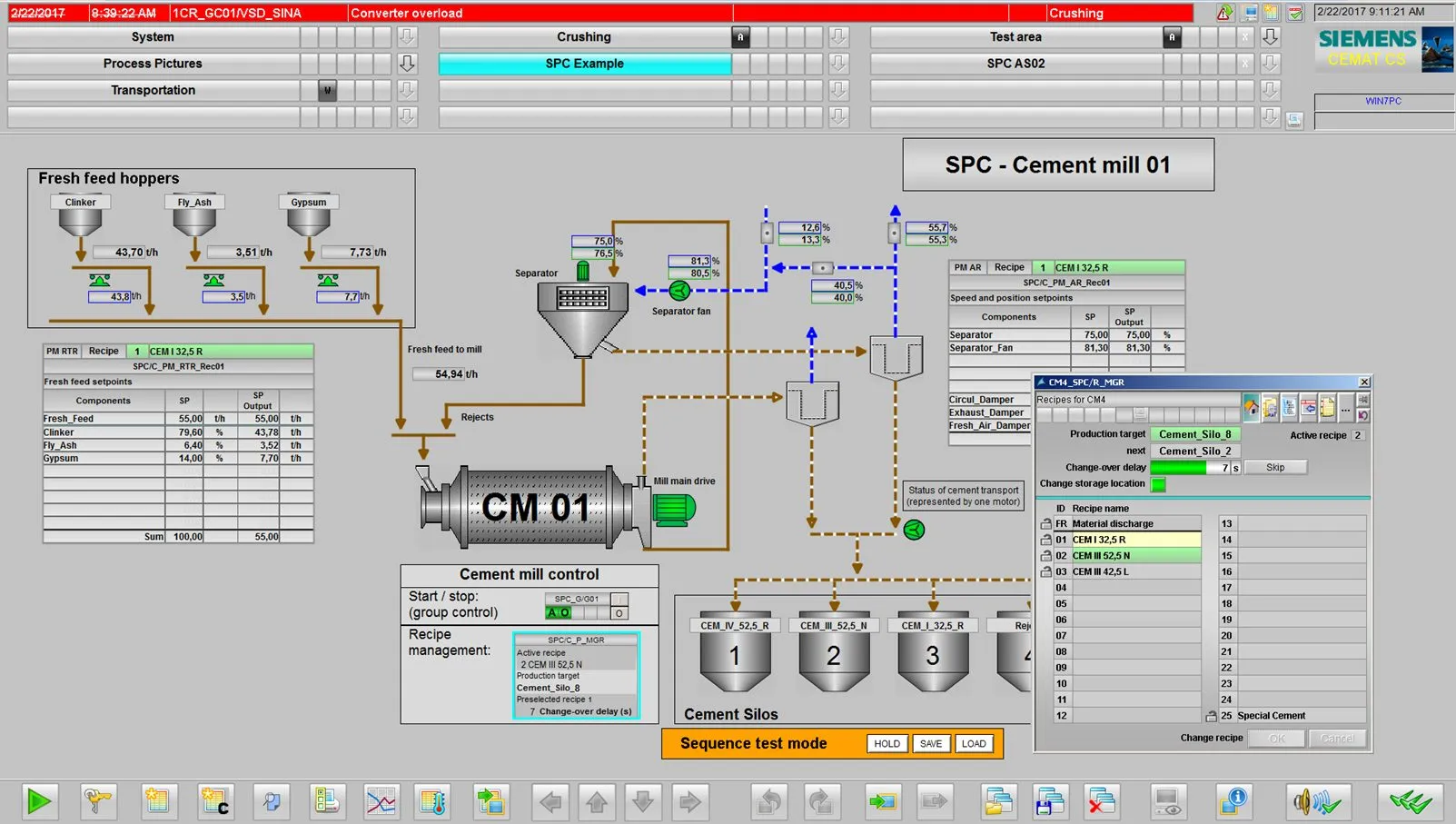

Since our foundation, we have successfully implemented the well-established CEMAT process control system across the building materials industry worldwide. This long-standing expertise enables us to automate cement, lime, and gypsum plants of all sizes – from medium to large-scale projects, both domestically and abroad.

Our practical know-how covers the full process chain: from quarrying and raw material preparation to kiln, cement grinding, and final dispatch.

CEMAT and MINERALS ADD-ONs

Beyond the extensive standard features of the CEMAT system, we have added a wide range of modules.

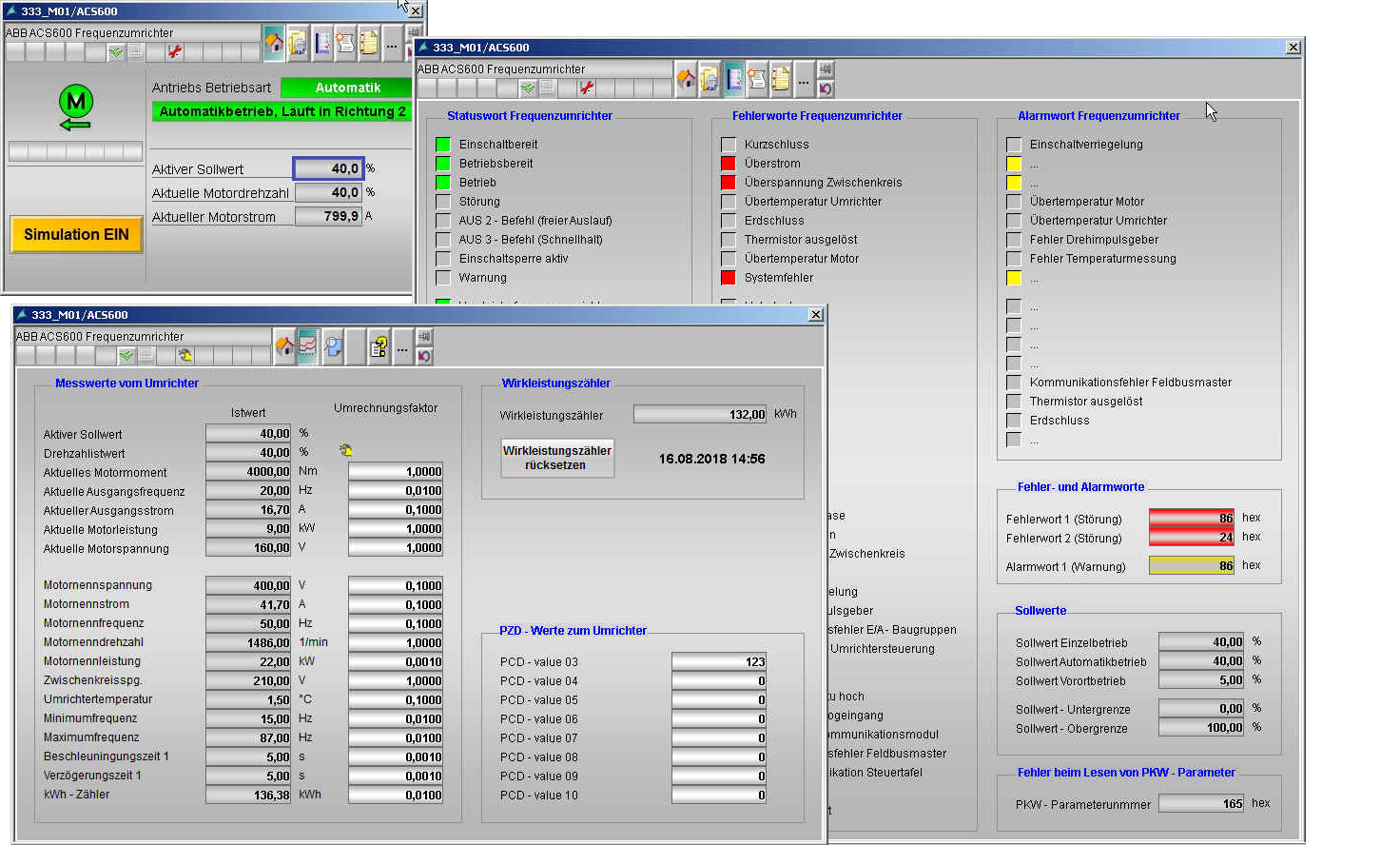

- Frequency converters (Siemens, ABB, etc.)

- Belt weighfeeders (Schenk, Pfister, Hassler, K-Tron)

- Mixing plants (OAS, Pfister)

- Robotic controls (ABB, KUKA, Reis)

- Power meters and energy counters (Sentron, KBR, etc.)

- Quality- and recipe-based route selection

All modules ensure standardized integration of diverse automation tasks into our customers’ central control system – for greater efficiency, transparency, and reliability.

Automate today, innovate tomorrow, excel forever.